The Role of a Plastic Injection Molding Factory in Modern Manufacturing

In the world of manufacturing, plastic injection molding stands out as one of the most efficient and effective methods of producing plastic components. A plastic injection molding factory is pivotal in this process, enabling businesses to scale production while maintaining high-quality standards. This article delves deeply into the intricacies of plastic injection molding, exploring its benefits, processes, and applications, ultimately laying out why it is a cornerstone within the manufacturing industry.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process for producing parts by injecting molten material into a mold. It is most commonly used for producing plastic parts but can also be adapted for metals and other materials. The flexibility of this process makes it suitable for a wide range of applications, from consumer goods to industrial components.

How Does the Plastic Injection Molding Process Work?

The plastic injection molding process involves several key steps:

- Material Preparation: Plastic pellets or granules are fed into a hopper and heated to melt them into a fluid state.

- Injection: The molten plastic is injected under high pressure into a mold cavity.

- Cooling: The injected plastic cools and solidifies within the mold.

- Mold Opening: Once solidified, the mold is opened, and the part is ejected.

- Finishing: The part may undergo additional processes such as trimming, painting, or assembly.

The Benefits of Using a Plastic Injection Molding Factory

Engaging with a plastic injection molding factory brings numerous advantages that can significantly benefit businesses:

- Cost-Effectiveness: Once the molds are created, the cost per part decreases significantly, making mass production economical.

- Speed: High-speed production capabilities allow for rapid manufacturing of high volumes of parts.

- Design Flexibility: Complex geometries can be achieved, allowing for innovative designs that meet specific requirements.

- Consistency: The automated nature of injection molding ensures consistent quality across all produced parts.

- Material Variety: A wide range of materials can be used, including thermoplastics, thermosets, and elastomers.

Applications of Plastic Injection Molding

The versatility of plastic injection molding means it serves countless industries. Here are some key applications:

1. Consumer Products

From plastic containers and toys to kitchen utensils and electronic housings, plastic injection molding allows for the mass production of consumer goods that are both functional and aesthetically pleasing.

2. Automotive Industry

In the automotive sector, a plastic injection molding factory produces a variety of components, including dashboards, door panels, and bumpers, contributing to lighter vehicles that improve fuel efficiency.

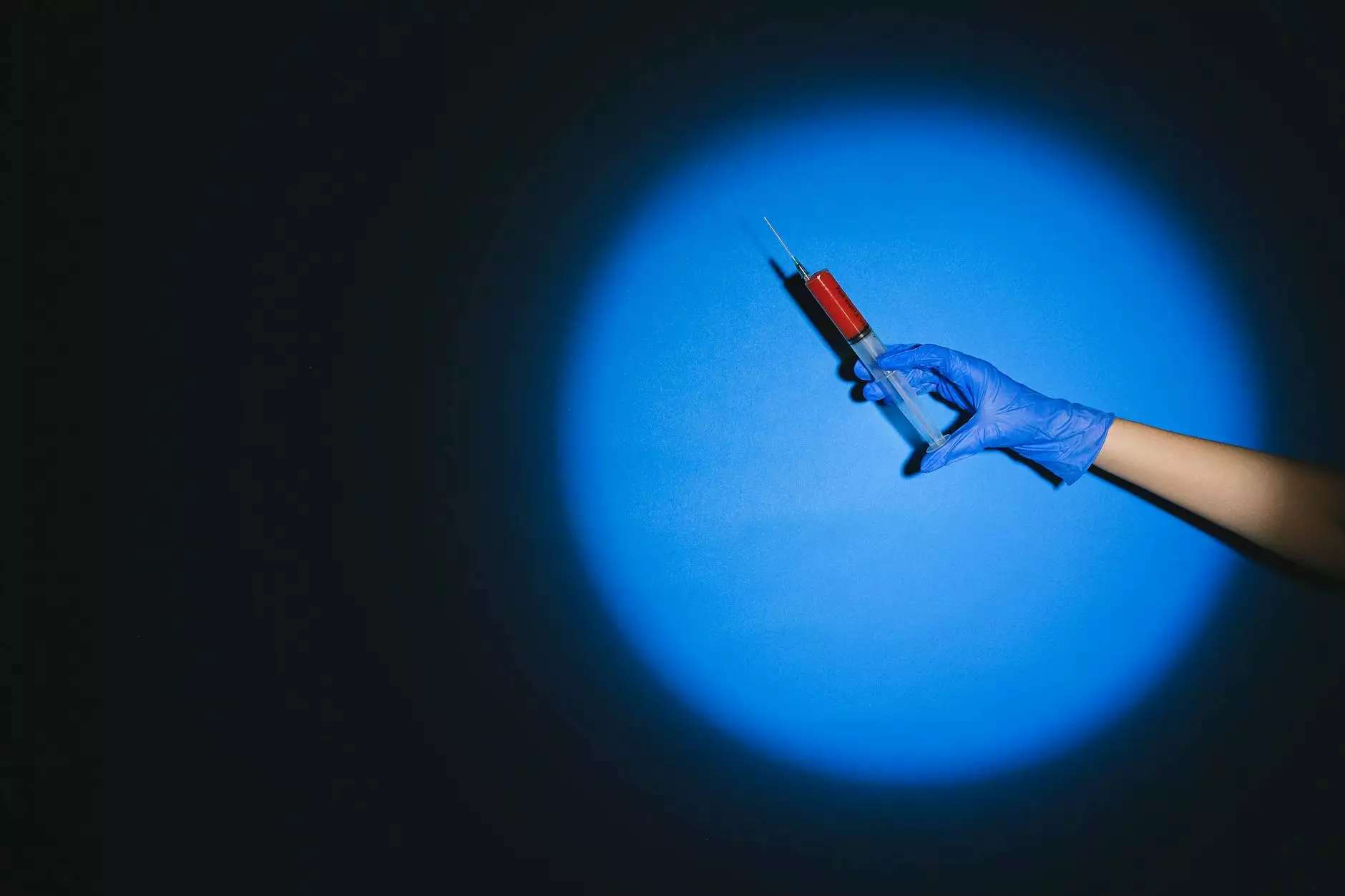

3. Medical Devices

The medical field utilizes injection molding for producing precise and reliable parts such as syringes, drug delivery systems, and surgical tools, emphasizing the importance of hygiene and safety.

4. Industrial Equipment

Many industrial applications rely on plastic injection molded parts for machinery components, housings, and other tools, ensuring durability and efficiency.

Key Considerations when Choosing a Plastic Injection Molding Factory

Selecting the right plastic injection molding factory is crucial for businesses looking to optimize production. Here are key factors to consider:

1. Expertise and Experience

Choose a factory with a proven track record and expertise in the specific materials and designs you require. Experience often translates to superior quality and less likelihood of defects.

2. Quality Assurance Processes

Ensure that the factory implements stringent quality control measures throughout the production process to maintain consistency and quality in the parts produced.

3. Production Capabilities

Consider the factory’s capacity to scale production. They should be able to handle small prototype runs as well as large-scale production efficiently.

4. Technology and Equipment

Modern machinery and technology can significantly improve production efficiency and reduce costs. Look for factories that invest in cutting-edge equipment.

5. Location and Logistics

The location of the factory can impact shipping costs and lead times. Choosing a factory that is geographically advantageous can benefit your overall logistics.

Challenges Faced by Plastic Injection Molding Factories

Despite the benefits, plastic injection molding factories face several challenges that can affect operations:

1. High Initial Costs

While the per-part cost lowers significantly at scale, the initial costs for designing and creating molds can be quite high. Businesses must be ready to invest upfront.

2. Material Limitations

Not all materials are suitable for injection molding. Understanding the limitations of different materials is critical for selecting the right one for each application.

3. Environmental Concerns

The manufacturing of plastic products raises environmental issues regarding sustainability. Factories must adopt eco-friendly practices to mitigate their impact.

Future Trends in Plastic Injection Molding

The industry is evolving, and various trends are shaping the future of plastic injection molding:

1. Sustainability Efforts

There is a growing demand for sustainable practices in manufacturing. The use of biodegradable materials and recycling initiatives is on the rise to decrease plastic waste.

2. Advanced Technology Integration

Integrating technologies like Industry 4.0, automation, and AI can enhance production efficiency, reduce downtime, and improve quality control.

3. Customization and Personalization

As consumer demand shifts towards personalization, factories will need to adapt their processes to offer tailored solutions, accommodating small batches with unique specifications.

Conclusion: Embracing the Power of Plastic Injection Molding

Engaging with a plastic injection molding factory opens up a world of possibilities for businesses aiming to manufacture high-quality plastic parts efficiently and cost-effectively. With advancements in technology and a better understanding of sustainable practices, the future of plastic injection molding looks promising. By understanding the process, benefits, and applications, businesses can unlock the potential that plastic injection molding offers, ensuring their competitiveness in an increasingly demanding market.

Get Started with DeepMould.net

If you are considering leveraging the capabilities of a plastic injection molding factory, look no further than DeepMould.net. With extensive experience in the industry, we are committed to providing top-notch injection molding services tailored to your specific needs. Get in touch with us today to learn more about how we can assist you in your manufacturing journey!